friction test setup|Friction Testing : supplier Coefficient of friction testing is a way to find out what happens when two items rub against each other. It can be used to determine the coefficient of friction (COF) value of everything from film .

web2 de out. de 1995 · 1 X 2. ATL. 15/12/2021 - Jogo 122. Ligga Arena - Curitiba - PR. Como foi o jogo. Copa do Brasil - Profissional - 2021. ATL. 4 X 0. ATH. 12/12/2021 - Jogo 121. .

{plog:ftitle_list}

Download unlimited PlayStation Portable ROMs for free only at ConsoleRoms. Variety of PSP games that can be played on both computer or phone.

The Coefficient of Friction Jig is able to measure the static and kinetic COF of many different materials including paper and plastics. http://www.universalgripco.com/#!astm-d1894/c1bp5The .The coefficient of friction (COF) tester is designed to measure the static and kinetic coefficients of friction of plastic film, plastics textile, sheeting, coated metals, leather printed cartons, packaging substrates, paper, and other surfaces. Kinetic Coefficient of Friction Testing: Apply a constant force or load on the upper sample to maintain a continuous sliding motion. Measure and record the force required to keep the upper.

The test platform can be set to travel at any one of three different speeds. The following procedure describes how to set the test platform speed. 1. Press both the Up and .

Technical Tips: Coefficient of Friction Testing

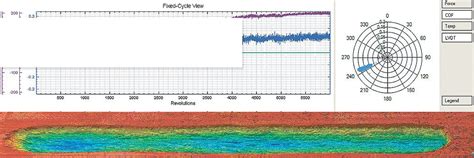

Coefficient of friction (COF) is the maximum value of the frictional force divided by the normal force. Coefficient of friction (COF) testing is used for a variety of materials from lubricants, to films to household items (ceramic tiles) to .Coefficient of friction testing is a way to find out what happens when two items rub against each other. It can be used to determine the coefficient of friction (COF) value of everything from film .The following tips explore some of the many factors that can affect Coefficient of Friction Tester (COF) measurements of your instrument analysis, particularly when comparing results and .Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module .

This post will help guide you through Coefficient of Friction fixture setup and operation on your universal testing machine. ADMET Coefficient of Friction fixtures are designed according to testing standards such as ASTM . Corrugated walls are widely employed in the construction of metal silos. Despite the long history of testing to establish bulk material parameters for silo design, there does not appear to be an established test procedure to directly determine the effective friction coefficient for a corrugated wall other than an adaptation of a classical direct shear test.

Force WIKA data sheet FO 51.69 WIKA data sheet FO 51.69 ∙ 08/2024 Page 1 of 3 Applications Friction clutch testing on chain hoists for: Service companies Chain hoist users Services and maintenance Test which surfaces create more friction, see how strong friction is, learn how to reduce friction, and even discover the side effects of friction. There are sliding friction experiments, a phone book friction experiment, a .

cell even if used on the same friction testing machine.) When pulling a steel cable over the same roll, it would be more appropriate to use a stiff testing system. 6.4 Initial friction force spikes will occur in many test systems. Test surfaces that are prone to blocking or interlock-ing of surface features are particularly prone to showing aWhen the ambient test temperature was 30 °C, the coefficient of friction remained above 0.43 for the first 700 s and then gradually decreased to above 0.41 until the end of the test.

The objective of the current project is to measure the friction force of the friction unit. In order to make the test results more obvious, the friction force obtained is expected to be stable with low amplitude oscillations. Therefore, the construction of the balance seat is a practical aspect that requires some further attention.Ensure that the test setup and the actual test you will be using on materials, assem-blies, or structures constitute no hazard to yourself or others. Make full use of all . The Friction Test Fixture consists of a horizontal plate, or table, and a moveable sled. Both the table and the sled are covered with the test material to perform the Annex D presents an empirical formula (also found in Moore et al. [2]) to evaluate the effective friction coefficient, μ eff, between the granular solid and the corrugated-wall interface by performing a weighted average of the tangent of the granular solid's internal friction angle, μ g = tan ϕ i, and its friction coefficient against a flat wall surface, μ w: (1) μ eff = 1 − a w μ g .

DIN-50324 Testing of Friction and Wear 3. Summary of Test Method 3.1 For the pin-on-disk wear test, two specimens are re-quired. One, a pin with a radiused tip, is positioned perpen-dicular to the other, usually a flat circular disk. A ball, rigidly held, is often used as the pin specimen. The test machine

The ‘miniature silo’ test: A simple experimental set-up to estimate the effective friction coefficient between the granular solid and a horizontally-corrugated cylindrical metal silo wall What is a Pin on Disk Test? Friction and wear (typically wear rates and wear resistance) characterization of materials is typically performed using various types of tribometers, while pin on disk test being probably one of the most common. The popularity of the method is due to its relative simplicity and abundance of the tribological contacts that can be well . This post will help guide you through Coefficient of Friction fixture setup and operation on your universal testing machine. ADMET Coefficient of Friction fixtures are designed according to testing standards such as ASTM D1894, ASTM D5458, ISO 8295, ISO 21182, and TAPPI T549. More information on our coefficient of friction fixture offerings can be found

Download scientific diagram | Friction Measurement Test Setup from publication: Experimental Determination and Analytical Model of Friction Torque of a Double Row Roller Slewing Bearing | In this .Original Article Design and development of a new portable test setup to study friction and wear Anahita Emami 1 , Seyedmeysam Khaleghian 2 , Tyler Bezek 3 and Saied Taheri 3 Abstract In this paper, a novel portable sliding friction and wear test rig is introduced. Unlike other laboratory-based test setups, this setup can be used for both indoor and outdoor experiments.ASTM D1894 is a standardized test method used for determining static (μ_s ) and kinetic (μ_k ) coefficients of friction of plastic film and sheeting. Plastic film is a widely used material in the packaging industry and includes many types of . The testing setup allows the friction coefficient to be estimated using the well-known Coulomb’s friction law. Experimental procedures were conducted to validate the new device. The experiments .

Friction is the force needed to start sliding an object (Static Friction), or the force needed to keep it sliding (Kinetic Friction), expressed as a ratio by dividing into the downward force of the mass. RDM Friction testers enable users to .

The following image shows a typical test setup. Friction is the force that counteracts relative movement between two touching surfaces and the coefficient of friction (µ) is the ratio between the force required to pull one surface over the other (f) and the force by which the surfaces are pressed against each other (N). μ= f/N

The test bench set up at LCC ( Figure 6) mimics the relative movement of the yarns during the braiding process “offline”. It has been designed in [3] to determine the effect of the friction . Although a rotary dynamic friction test bed was available to the authors, it had its limitations, such as low speed, inducement of lateral force, and the limitation of testing samples with different shapes. This paper will explain the process of designing and manufacturing a novel test setup for measuring friction and wear of the tire.The Bearing Cage Friction Test Rig (BCFTR) was designed and developed to directly measure the friction between the cage and rollers of a variety of ball bearings. The rig features a high precision ATI MINI 40 load cell that measures forces and torques about the X Y and Z axes. . The test setup is mainly used for: Identification of maximum .

Chinese Tearing Resistance Testing

custom Tearing Resistance Testing

ASTM D 5183 describes the use of the four-ball test to study friction as function of load at 75 °C and 600 rpm (0.23 m/s). In this test method, a run-in with white oil is performed prior to the run with the test oil. . since local lubricant depletion is typically reached. Thus, this test setup is mostly used for boundary lubrication studies .Explore the forces at work when pulling against a cart, and pushing a refrigerator, crate, or person. Create an applied force and see how it makes objects move. Change friction and see how it affects the motion of objects.

Ensure that the test setup and the actual test you will be using on materials, assem-blies, or structures constitute no hazard to yourself or others. Make full use of all . The Friction Test Fixture consists of a horizontal plate, or table, and a moveable sled. Both the table and the sled are covered with the test material to perform the

Download scientific diagram | Friction test set-up. from publication: Tribological behavior of a silicon carbide/carbone dry contact | The development of new high-performance mechanical seals .January/February 2009 EXPERIMENTAL TECHNIQUES 45 TEST SETUP FOR FRICTION FORCE MEASUREMENTS Fig. 2: Large-scale bearing test setup Fig. 1: General view of the test rig without frame The bushing of the test bearing has a lever arm (7) attached to it. This lever arm connects the bushing to a load cell (8) that measures the acting friction force .

Zero Friction Cycling, run by former policeman Adam Kerin, presents itself as a trusted source for friction-reducing products, but behind the scenes, a lack of engineering knowledge and unverified testing methods raise red flags. Despite requesting sensitive industry data without doing foundational research, Kerin's approach appears more focused on .

Linear Wear Friction Testing

Guide to Coefficient of Friction Testing

Resultado da Assistir Companheiros de Viagem online: streaming, compre ou alugue . Você pode assistir "Companheiros .

friction test setup|Friction Testing